How can we help?

Since 2007, we’ve provided creative lighting product design, manufacture, and support, to clients all over the world.

We’re agile and flexible, with the ability to tackle large projects on challenging timescales.

We’re used to demanding clients, and working in creative environments where the need can change from one moment to the next.

Our cutting-edge engineering experitise is our unique strength, giving us the ability to apply the most appropriate technique to a task, rather than settle for second best.

Design

Our vast experience, and agile approach to engineering, allows us to design products and systems in record time.

We prototype and refine in-house for maximum speed and cost effectiveness.

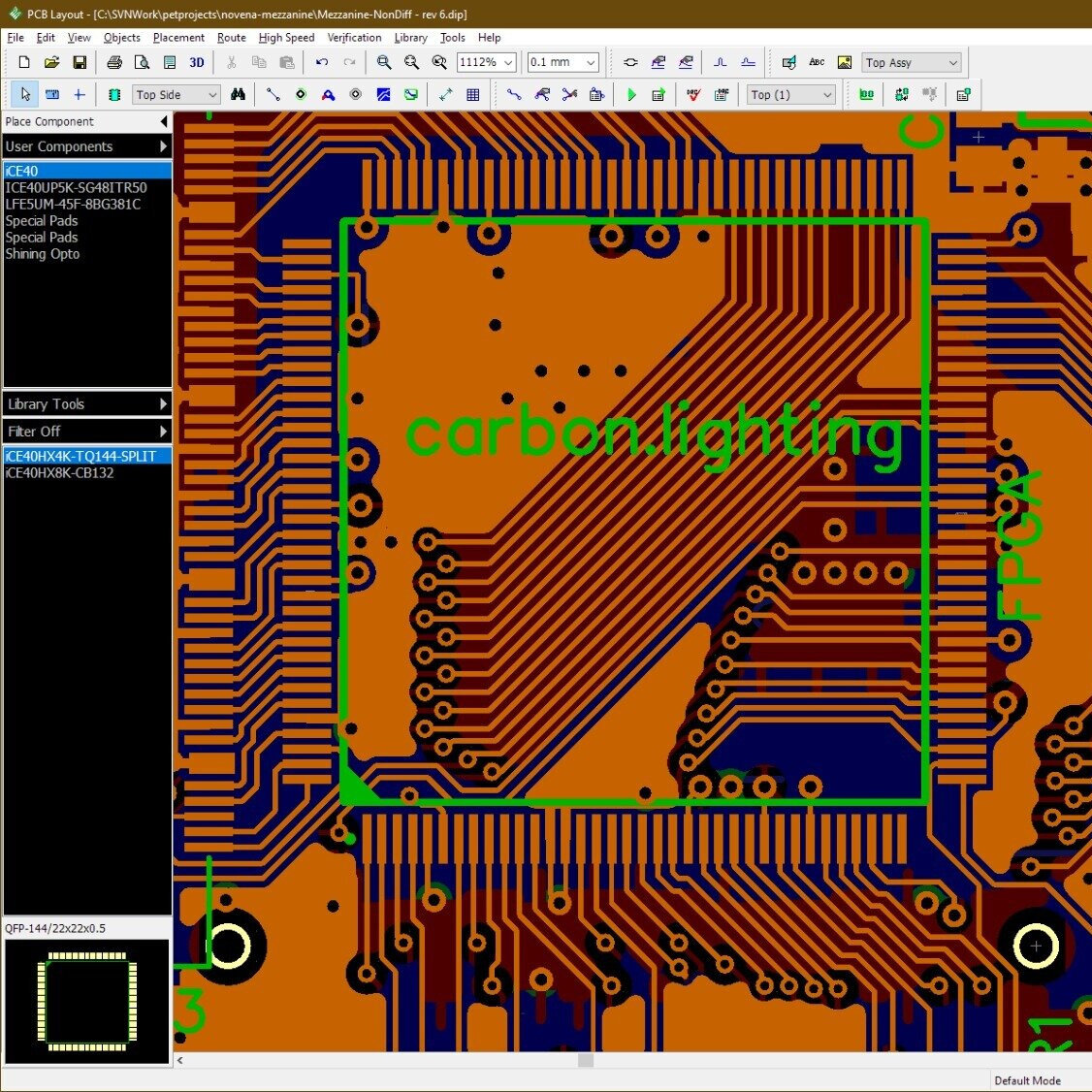

Our electronics design service comprises of circuit board design, component choice, firmware programming and testing.

Our product design includes all component metal and plastic parts.

As we manufacture our own products in-house, this gives us a unique insight into design challenges and process optimisation.

We have extensive thermal and optical design experience. Often LED technology is not robustly designed from an engineering and manufacturing perspective. Our experience allows us to offer a level of quality and reliability as standard which is difficult for others to match.

Manufacture

One of our greatest strengths lies in our manufacturing ability.

Our workshops contain an eclectic range of equipment, and we specialise in producing complete finished products in-house.

By keeping control over the entire manufacturing process we can produce exceptional quality, and precise attention to detail, while maintaining a firm grip on costs.

Processes undertaken in-house include:

Electronics assembly - Surface Mount & Thru Hole, programming, testing and final product assembly.

CNC Machining - Turning and 4-axis milling of plastics, ferrous and non-ferrous metals.

3D Printing - FDM and SLA technology using our farm of 20 machines for mass production. Printing in ABS, PLA, TPU, PTFE and other materials.

Plastics - Mould Making, Casting and Rotocasting of plastic parts in various materials with a wide range of surface finishes.

Support

Many of our projects are massive in scale, and require dedicated installation and maintenance support on-site. We provide knowledgeable and well-equipped teams, and are well known for our attention to detail.

Our support services are provided globally, and compliment our products throughout their design life.

We have rare experience working in challenging environments, and our staff work across timezones, languages, and cultures.

Using modern communication methods, and every tool at our disposal, we offer a personalised and tailored solution to your support requirements.